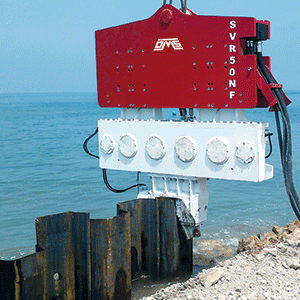

SVR 50 NF - Crane Suspended Vibratory Pile Hammer

0 Kommentare

/

https://www.omsvibro.de/wp-content/uploads/2017/07/OMS-Side-Grip-Vibro-Hammer.jpg 504 283 omsvibro https://www.omsvibro.de/wp-content/uploads/2016/06/OMS_LOGO.png omsvibro2017-07-14 17:12:442017-08-08 15:18:44Side Grip Pile Driver

https://www.omsvibro.de/wp-content/uploads/2017/07/OMS-Side-Grip-Vibro-Hammer.jpg 504 283 omsvibro https://www.omsvibro.de/wp-content/uploads/2016/06/OMS_LOGO.png omsvibro2017-07-14 17:12:442017-08-08 15:18:44Side Grip Pile Driver

What is Vibratory Hammer?

Learn "What is Vibratory Hammer" from a Vibro Hammer Manufacturer!As…

https://www.omsvibro.de/wp-content/uploads/2017/03/Rental-Vibro-Hammer-SVR80NF.png 300 300 omsvibro https://www.omsvibro.de/wp-content/uploads/2016/06/OMS_LOGO.png omsvibro2017-03-03 16:59:142018-05-02 13:46:56Vibro Hammer Rental

https://www.omsvibro.de/wp-content/uploads/2017/03/Rental-Vibro-Hammer-SVR80NF.png 300 300 omsvibro https://www.omsvibro.de/wp-content/uploads/2016/06/OMS_LOGO.png omsvibro2017-03-03 16:59:142018-05-02 13:46:56Vibro Hammer Rental

Excavator Mounted Vibrohammer OVR 120 S

Excavator Mounted Vibrohammer OVR 120 S

OVR Series vibro hammer…

https://www.omsvibro.de/wp-content/uploads/2016/12/Happy-New-Year-2017.jpg 261 454 omsvibro https://www.omsvibro.de/wp-content/uploads/2016/06/OMS_LOGO.png omsvibro2016-12-19 18:21:062016-12-20 11:33:18Happy New Year - 2017

https://www.omsvibro.de/wp-content/uploads/2016/12/Happy-New-Year-2017.jpg 261 454 omsvibro https://www.omsvibro.de/wp-content/uploads/2016/06/OMS_LOGO.png omsvibro2016-12-19 18:21:062016-12-20 11:33:18Happy New Year - 2017

Port Said Project in Egypt with SVR 200 NF

OMS – Crane Suspended Vibratory Hammer SVR 200 NF in Egypt

OMS…

Crane Suspended Vibro Hammer SVR 101 NF

As continuing of our successful story in Egypt, we…

Crane Suspended Vibratory Hammer SVR 200 NF

OMS Crane Suspended Vibratory Hammer SVR 200 NF and its…

Vibratory Hammer SVR 200 NF - Driving Pipe in Egypt

OMS Crane Suspended Vibratory Hammer SVR 200 NF and its Power…